Five-axis 3D printer Epit 5.1

A new stage in the development of FFF 3D printing technologies

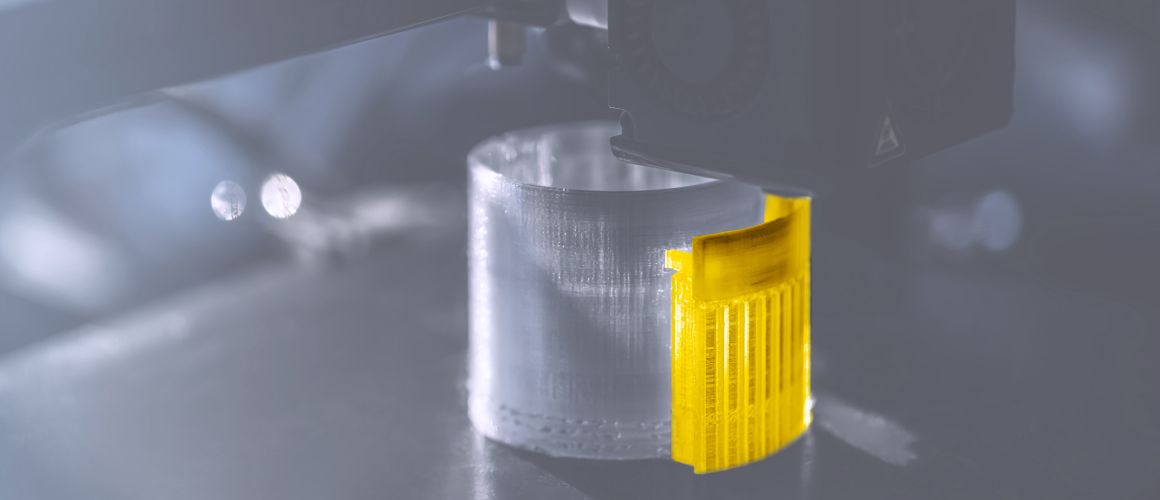

This is a hardware and software complex for 3D printing of polymer products

EPIT 5.1

Our 3D printer is equipped with a rotary-tilt table, which provides five-axis control of the printing process

5 axis

Get to know the advantages of our technology

Five-axis 3D printer Epit 5.1

Get to know the advantages of our technology

A new stage in the development

of FFF 3D printing technologies

of FFF 3D printing technologies

This is a hardware and software complex for 3D printing of polymer products

EPIT 5.1

Our 3D printer is equipped with a rotary-tilt table, which provides five-axis control of the printing process

5 axis

Advantages over

3-axis printing

3-axis printing

Classic three-axis printers require the use of supporting structures when printing hinged elements. On average, users have to use support in 70% of cases.

solution cons:

Support can not be removed from all planes

Need to remove support and modify the model

Increase of print time

Increase of material costs

How EPIT printers work

Due to the use of a turntable, the body of the model is oriented in such a way as to minimize the use of supports, and build hinged elements based on already printed parts

Benefits of 5-axis printing

Strength

Due to the possibility of cross-layering, the strength increases significantly

Convenience

You needn't to spend time and effort of removing support

Profitability

Species surfaces of products do not suffer from traces of support

Opportunities

You can print products that are not available for a traditional 3D printer

Productivity

Up to 2x better productivity than traditional 3D printers

Profitability

Material costs are reduced by 30%

Why

choose EPIT?

choose EPIT?

EPIT 5.1 printers come with FASP software — our own design of a slicer for five-axis printing. Thanks to the use of a full-fledged software and hardware solution, our customers receive all the benefits of five-axis 3D

A full desktop expands the capabilities of five-axis printing

Ball-and-screw pairs provide precision and durability

Closed working chamber provides protection against warping of the part

Steel frame provides rigidity of structure

High-performance electronics

nozzle

from 2 to 1.0 mm

printing speed

up to 150 mm/s

print accuracy index

12

table tilt accuracy

0,02˚

thread diameter

1,75 mm

nozzle temperature

up to 320˚

table temperature

up to 150˚

overall dimensions

530х440х870 mm

working space in 5 axes

working axes

240х240х240 mm

5

printing technology

FDM

design type

Delta

minimum layer thickness

0,05 mm

head positioning accuracy

10 µm

SBS

ASA

WAX

TRU

PA

PP

PLA

SAN

TPE

ABS/PC

ABS

PET-G

Available materials

Epit printers are a step forward

postprocessing required

no

reduced printing time

28%

reduction of material costs

24%

support

costs

costs

0 gr.

Dispenser housing

Camera bracket

0 gr.

support costs

31%

reduction of material costs

22%

reduced printing time

no

postprocessing required

Skate

8 gr.

support costs

35%

reduction of material costs

36%

reduced printing time

no

postprocessing required

Branch pipe

0 gr.

support costs

38%

reduction of material costs

41%

reduced printing time

no

postprocessing required

For whom are EPIT 5.1 printers suitable

Production and Repair Units

Research centers

R&D Business Units

LLC «Voploschenye»

ITN 1650350558

PSRN 1171690064215

ITN 1650350558

PSRN 1171690064215

Polymer material in the form of a rod is supplied to the printhead. In the head, the material melts and is laid out on the working surface layer by layer, while the head moves in space above the dekstop.

HOW FFF TECHNOLOGY WORKS

Supporting structure

Desktop

Printed model

Printhead

Polymer material in the form of a rod is supplied to the printhead. In the head, the material melts and is laid out on the working surface layer by layer, while the head moves in space above the dekstop.

HOW FFF TECHNOLOGY WORKS

Printhead

Printed model

Desktop

Supporting structure

Submit a request

Submit a request